Chinangwa

Iyi chenjedzo yekuchengetedza inosimbisa njodzi yekutadza kwekongiri pombi yekuendesa mitsara inosanganisira kutadza kwekupedzisira fittings.

Mabhizinesi anoenderana nemagumo ekupedzisira kune makongiri ekutakura hosi uye mapaipi anofanirwa kutevedzera uye kunyora einjiniya maitiro uye kupa ruzivo nezve nzira dzekuongorora kune vatengi.

Varidzi vepombi yekongiri vanofanira kuwana ruzivo kubva kune vanopa pombi nemapombi pamusoro penzira dzekugadzira dzinoshandiswa uye nzira dzekuongorora dzakakodzera.

Background

Pave nezviitiko muQueensland uko mitsetse yekutakura yakundikana uye yakapfapfaidza kongiri pasi pekumanikidzwa.

Kukundikana kwaisanganisira:

- rubber delivery hose kukundikana

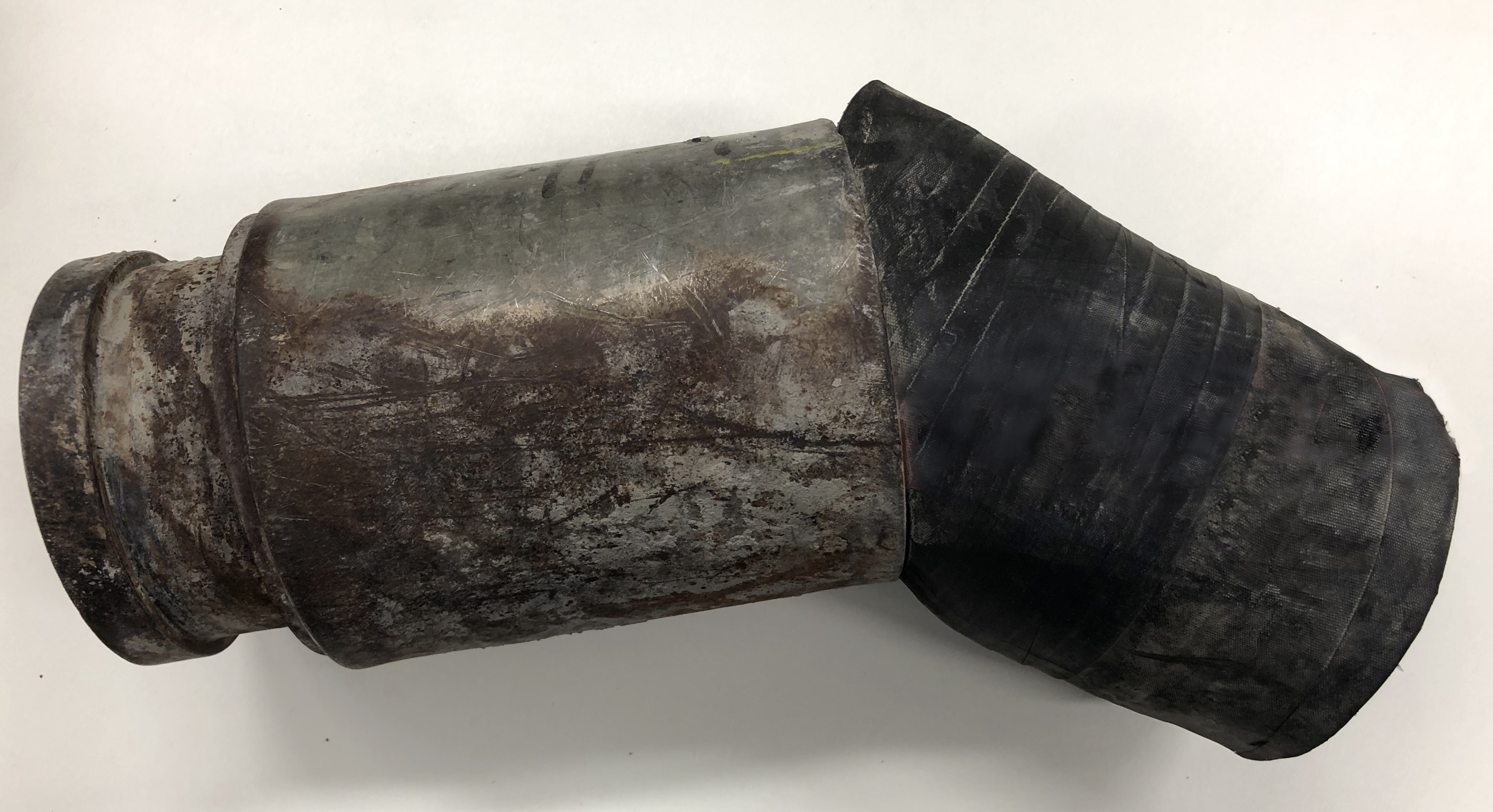

- kubatanidza dzinde kutsemuka nemagumo kubvaruka (tarisa Mufananidzo 1)

- kupera kwakakodzera kutanga kupatsanurwa kubva papombi yerabha (tarisa Mufananidzo 2) nekongiri yekupfapfaidza kunze kwepakakoromoka.

- flange kutsemuka nekutyoka kubva pasimbi 90-degree, 6-inch kusvika 5-inch reducer bend, iri pane hopper (tarisa Mifananidzo 3 uye 4).

Kongiri yekupomba kudzvanywa inogona kudarika 85 bar, kunyanya kana zvivharo zvikaitika.Zvese izvi zviitiko zvine mukana wekukuvadzwa kwakanyanya kana vashandi vaive pedyo nepakaitika kukundikana.Mune chimwe chiitiko, windscreen yemotokari yakapwanyika anenge mamita gumi nemashanu kubva ipapo.

Yakatsemuka uye yakundikana chikamu chehose hunde

Swaged magumo ekupedzisira akapatsanurwa kubva papombi

Yakakundikana flange pasimbi inoderedza bend

Zvinokonzera

Hoses uye kupera fittings zvinogona kukundikana nekuda kwe:

- chiyero chekumanikidza kwepombi yekongiri inopfuura iyo yerabha hose kana magumo ekupedzisira

- kushivirira kusina kururama pazvikamu zvemukati nekunze zvekubatana

- iyo nzira yekugezera kana crimping haienderane nezvinodiwa nemugadziri

- zvisizvo zvakatemwa zvehosi yerubha

- kupfeka zvakanyanya-kunyanya pachikamu chemukati chekukodzera kubva kuyerera kwekongiri.

Flanges pamapombi esimbi anogona kukundikana nekuda kwe:

- kukwenenzverwa kwakashata nekuda kwemaelectrode asiri iwo, kugadzirira kwakashata, kushaikwa kwekupinda, kana zvimwe zvisizvo zvewelding

- maflange nemapombi ari kugadzirwa kubva kumhando dzesimbi dzinogona kunetsa kupinza

- kusaenderana kwakashata kwemaflange nemapombi (kureva kuti flange haikwane pamagumo epombi)

- kusabatwa zvakanaka kwepombi flange (kureva kugeza flange kana pombi nesando kana pombi yepedyo uye/kana hose clamp isina kurongeka)

- simbi dzepombi dzisina kukwana zvakanaka (semuenzaniso saizi isiriyo, kuvaka kongiri).

Chiito chinodiwa

Varidzi vepombi yekongiri

Varidzi vepombi yekongiri vanofanirwa kuona kuti kudzvanywa kwepombi yekongiri hakupfuurire yepombi.Semuyenzaniso, kana pombi yakayerwa pa85 Bar kongiri pressure hazvitenderwi kuti pombi yesimbi itsiviwa nerabha hose ine mwero mukuru we45 Bar.Varidzi vanofanirawo kutora matanho ane musoro kuti vave nechokwadi chekuti chirongwa chesimbisiro yemhando inotevedzwa panguva yekubatanidza zvigadziriso zvekupedzisira kuitira kuti kutadza kwemagumo ekupedzisira kudziviswa.Zvinowanzo kuve nyore kuwana chitupa kubva kumutengesi wepano kana uchitenga michina.

Kana muridzi wepombi yekongiri achipinza zvinhu kubva mhiri kwemakungwa, zvingave zvakanyanya kuoma kuwana ruzivo rwakavimbika nezvemaitiro ekugadzira.Izvi ndizvo zvinoitika kana mutengesi wemhiri kwemakungwa asingazivikanwe kana pasina chiratidzo chemugadziri.Vagadziri vasina kutendeseka vave vachizivikanwawo nekukopa mazita nezviratidzo zvevagadziri, saka kumaka kwezvigadzirwa chete kungasapa humbowo hwakakwana hwekuti chigadzirwa chacho chakakodzera chinangwa.

Muridzi wepombi yekongiri anotora midziyo kubva mhiri kwemakungwa anotora basa remutengesi pasi peWork Health and Safety Act 2011(WHS Act).Iye anotora kunze kwenyika anofanira kuita, kana kuronga kuve aita, chero kuverenga, kuongorora, kuyedzwa, kana kuongorora michina yekudzora njodzi yekuchengetedza.

Vatengesi vepombi uye hoses

Vatengesi vemahosi nemapombi ane end fittings vanofanirwa kuve nechokwadi chekuti chirongwa chekusimbisa mhando chinoteverwa uchibatanidza mafirita ekupedzisira uye kuti ruzivo rwechirongwa ichi rwunowanikwa kune mutengi.

Vatengesi vanofanirawo kupa mirairo yakanyorwa pamusoro pemaitiro ekushanda echigadzirwa pamwe chete nenzira dzekuongorora dzinoshandiswa.

Kana mutengesi akasungirira zvinoperera papombi kana hosi, mutengesi anotora mabasa evagadziri pasi peWHS Act mukuwedzera kune aya mabasa evanotengesa.

Kuisa magumo ekupedzisira kune hoses

End fittings inonamirwa kune rabha hose uchishandisa nzira mbiri, crimping uye swaging.Neyo crimping nzira, masimba ekumanikidza anoshandiswa radially kune yekunze chikamu (ferrule) yemagumo inokodzera nemukati hunde yakaiswa mukati mekupera kwepombi.Iyo yakashongedzwa yekupedzisira yekukodzera inogona kunyatso kucherechedzwa nekujeka indentations kunze kweiyo yekupedzisira kuenderana (tarisa Mufananidzo 5).Neyo nzira yekugezera, kuguma kusungirirwa kunosungirirwa kune hose apo kuguma kwekupedzisira kunosundirwa kumagumo epombi pasi pe hydraulic pressure.Kunyangwe kuchave nekumwe kumaka pamagumo akakodzera kubva mukugadzira maitiro, swaged magumo ekugadzirisa haana pachena indentations senge crimped end fitting.Mufananidzo 2 muenzaniso weiyo yakashongedzwa magumo akakodzera ayo akapatsanurwa chikamu kubva papombi.

Kunyangwe crimping uye swaging zvakasiyana zvakanyanya, nzira dzese dziri mbiri dzinotsamira pakushandisa mhando dzemhando dzekushivirira pamwe nekuona kuti nzira yakaoma yekubatanidza magumo ekupedzisira inoteverwa.

Vagadziri vehosi vanozongo simbisa chete kuti hose yavo inokwanisa kumirisana nekongiri yakatsanangurwa kana migumo yemhando yepamusoro yaiswa.Vamwe vagadziri vepombi vanoshanda pasi pechirevo che amatched pairuko ivo vanozongovimbisa hose yavo kune yakanyanya kudzvanywa, kana magumo ekugadzirisa kubva kune mumwe mugadziri achishandisa inovimbika crimping kana swaging nzira inoshandiswa.

Kana uchiunganidza magumo ekupedzisira pahosi simbisa:

- kutevedzera ese emamiriro akatsanangurwa nehose uye / kana magumo akakodzera mugadziri

- iyo hose zvinhu uye zviyero zvakakodzerwa nekupomba kongiri uye yekumisikidza yemhando chaiyo yekugumisira

- saizi yekunze uye yemukati zvikamu zvekukodzera kunofanirwa kunge kuri mukati mekushivirira kunotsanangurwa nemugadziri wepombi kana akakodzera mugadziri wezviyero zvepombi inoshandiswa.

- nzira yekubatanidza kuguma kwekupedzisira inofanira kuenderana nezvinodiwa zvemugadziri (ruzivo kubva kumugadziri wepombi inogonawo kudiwa).

Kuedzwa kwekupedzisira kwekugadzirisa ndiyo imwe nzira yekubatsira kuratidza kuvimbika kwekubatana.Kuyedzwa kwehumbowo hwezvese zvigadziriso kana kukuvadza kuyedzwa kwemasample inzira dzinogona kushandiswa.Kana kuyedzwa kwehumbowo kuchiitwa, nzira yekuyedza inofanirwa kuona kuti yakafanira uye hose haina kukuvara.

Kutevera kusungirirwa kwekupedzisira kuenderana kune hose, iyo yekumisikidza inofanirwa kuve yakamisikidzwa neruzivo rwenhamba yebatch uye chiratidzo chekuzivikanwa chekambani inosungirira iyo yekupedzisira.Izvi zvichabatsira nekutsvaga uye kutendeseka kwemaitiro egungano.Nzira yekumaka haifaniri kukanganisa kuvimbika kwegungano repombi.

Kana paine kupokana pamusoro pemaitiro ekugadzira kana kuyedzwa zvine chekuita nekuguma kwakakodzera, rairo yemugadziri wemidziyo yekutanga (OEM) inofanirwa kuwanikwa.Kana izvi zvisipo, zano reinjiniya ane hunyanzvi hunofanirwa kuwanikwa.

Ruzivo rwakanyorwa pamusoro penzira yekubatanidza iyo yekupedzisira yekukodzera inofanirwa kuchengetedzwa nebhizinesi rinobatanidza kupera kwakakodzera uye rinofanira kuwanikwa pakukumbira.

Welding flanges kune simbi pombi

Welding flanges kune simbi pombi inoshandiswa kupomba kongiri inyaya yakaoma uye inoda mazinga epamusoro ehunyanzvi hwekupinza uye hunyanzvi kuti ive nechokwadi chekuti welding process inoguma nechigadzirwa chemhando.

Izvo zvinotevera zvinofanirwa kuve nechokwadi:

- Pombi chete yakanangana nekupomba kongiri ndiyo inofanira kushandiswa.Kusati kwave nemoto, panofanirwa kuve neimwe nzira yakavimbika yekuona kuti pombi nemaflange ndiyo chaiyo mhando yakarairwa.

- Iyo weld yakatarwa inofanirwa kuenderana nepombi uye flange zvinhu maitiro uye kumanikidzwa kutsanangurwa kwepombi iri kuputika.Mashoko anofanira kuwanikwa kubva kumugadziri wepombi panyaya iyi.

- Welding inofanira kuenderana neyakadzama weld process inosanganisira kusarudzwa kwe electrode, pre-heating mirairo (painoda) uye kushandiswa kwenzira yewelding inokurudzirwa nemugadziri wepombi.

- Kuita kuyedza kunoparadza pane bvunzo sampu yekuona iyo welding nzira inokodzera chinangwa.

Kuongororwa kwehosi nemapombi

Varidzi nevashandisi vekongiri yekupomba michina vanofanirwa kuona kuenderera mberi kwekuongorora kwepombi nemapombi kunoitwa.Nzira dzekuongorora uye nguva dzekuyera ukobvu hwepombi dzakatsanangurwa muConcrete Pumping Code Yekudzidzira 2019(PDF, 1.97 MB).Zvisinei, nekuwedzera, chirongwa chekuongorora chinofanira kushandiswa kumagumo ekugadzirisa pahosi dzerubha uye flanges pamapombi esimbi.

Kuongororwa kwehosi

Ruzivo rwakanyorwa pamusoro pekuongorora hose (kureva kubva kuOEM), runofanira kupihwa nebhizinesi rinoenderana nemagumo uye izvi zvinofanirwa kupfuudzwa nemupi wepombi kumushandisi wekupedzisira.

Purogiramu yekuongorora inofanira kusanganisira kuongorora kusati kwashandiswa uye nguva yekuongorora nguva nenguva zvichienderana nehuwandu hwekushandiswa uye nzvimbo yekushanda.

Chirongwa chekuongorora chinofanira kusanganisira:

- ongororo yemukati ine mwero wakakwana wechiedza chekutarisa machubhu epombi akakora, hapana jira remachira kana simbi inosimbisa yakafumurwa, hapana kuvharika, kuputika, kucheka kana misodzi yechubhu ye liner, uye hapana zvikamu zvakadonha zvechubhu yemukati. kana hose

- kuongorora kwekunze kwekutarisa kukuvadzwa kwechivharo kunosanganisira kuchekwa, misodzi, abrasion inoburitsa zvinhu zvinosimbisa, kurwisa kwemakemikari, kinks kana nzvimbo dzakadonha, nzvimbo dzakapfava, kuputika kana mamiriro ekunze.

- kuongororwa kwemagumo ekupedzisira kwekupfeka zvakanyanya uye kutetepa kwemadziro emadziro

- kuongororwa kwekuona kwekupedzisira kwekugadzirisa kwezvimedu.Kana paine kusahadzika kupi kana paine nhoroondo yekutsemuka, kuongororwa kusingaparadze kunogona kudikanwa

- chekutarisa magumo ekuisa akasimba uye haasi kutsvedza kubva papombi nekuda kwekuchembera kana kubva kumagetsi ekudhonza mitoro.

Kuongorora welded flanges pane simbi pombi

Pamusoro pekuyera kuyera kwepombi yesimbi (inotsanangurwa muCode of practice) uye kutarisa pombi yekukuvara, zvakakosha kutarisa maflange papombi yekupomba pombi.

Chirongwa chekuongorora chinofanira kusanganisira kuongorora kwe:

- welds dzekutsemuka, kushaikwa weld, weld undercut uye weld kuenderana

- maflange ekutarisa kuti haana kuremara uye haana mavanga esando

- pombi inopera nechomukati kuitira kusaenzana kupfeka uye kuputika

- flanges kuitira kuti vasununguke kubva kune kongiri kuvaka-up uye zvimwe zvinhu zvekunze.

Nguva yekutumira: Aug-07-2021